Nemesis 9600

The NEMESIS 9600 is a heavy-duty floor type universal hardness tester most suitable for harsh testing conditions of very large parts. This floor type frame reaches a height of 2 meters and offers a workspace of not less than 650 mm height and a throat depth of 395 mm from spindle center.

Read more- Scales: Rockwell, Superficial Rockwell, Brinell, Vickers, Knoop, HVT & HBT, Plastic ISO 2039/1, Carbon.

- Test forces: 200 gf - 3000 kgf.

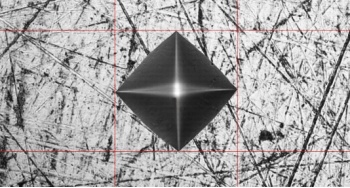

- Camera: 18 Mega pixel, Full HD camera system, with zoom and autofocus.

- Overview camera: Full HD optical zoom stage overview camera.

- 8 position turret: 3 indenters, 3 objectives, Class 2 laser for positioning and optional integrated overview camera.

- Objectives: 0.7x, 2.5x, 5x, 10, 20x, 40x, 60x, 100x.

Fully automatic, Load cell, closed loop, force feedback. - Load app. system control: Fully automatic, Load cell, closed loop, force feedback. Fully integrated Windows Controller, SSD hard disk, Windows 10 operated, IMPRESSIONSTM advanced workflow software, includes automatic measurement, keyboard & mouse.

- Display: 15” full color touch screen.

- Advanced output: Multi USB, CSV files, single readings, reports, printer, Q-DAS certified.

- Software: No. of tests, Mean, St. Deviation, Min., Max., Range, CP, CPk, individual readings list, storage memory, Dwell time, test force setting, scale selection, calibration etc.

- Illumination: Power LED.

- Z-Axis: CNC motorized, ball bearing slide, with fast up down and digital scroll wheel for fine adjustment.

- XY-Stage: Manual, motorized stages or/and anvils or work tables at choice.

- Workpiece acc.: 650 mm(H) X 395 mm (D).

Univerzální tvrdoměr Nemesis 9500

Univerzální tvrdoměr Nemesis 9500

Univerzální tvrdoměr Nemesis 9500

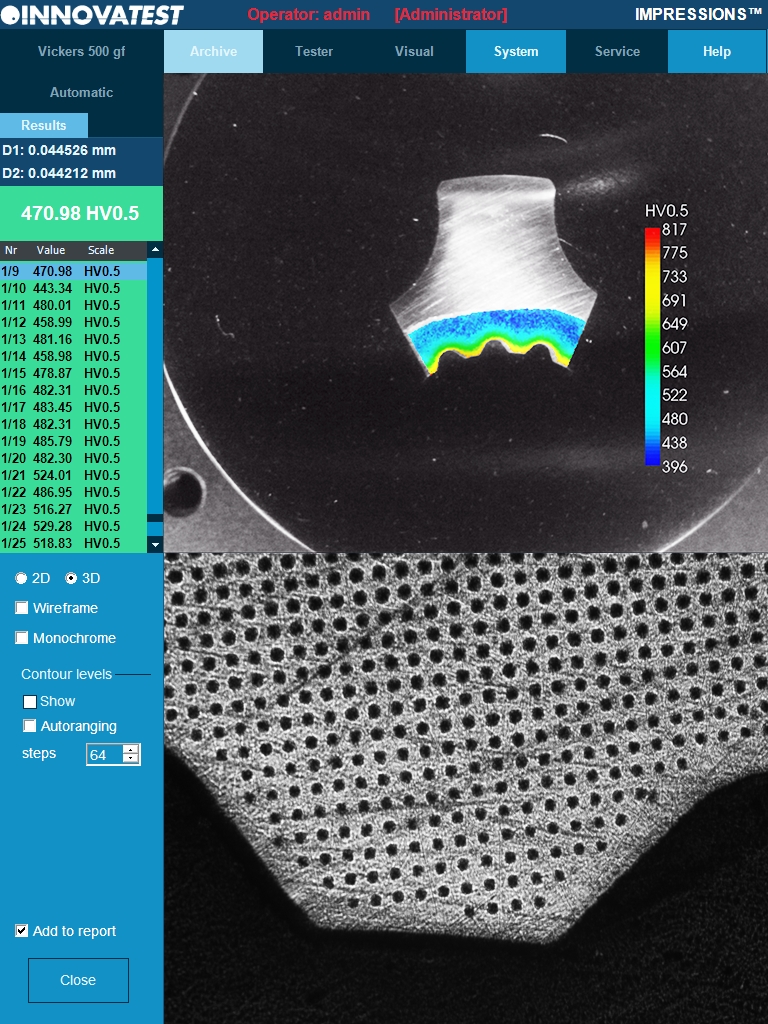

Impressions - software

Impressions - software 2D scan