Optical measuring systems

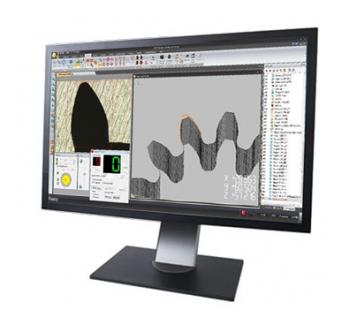

Optical measuring systems provide one of the most accurate methods of inspecting dimensions, with errors of only 0.001 mm. They can be used to measure along the X, Y and Z axes in any workshop or laboratory. Manual profile projectors with measurement microscopes allow quick inspection of basic dimensions or more complex calculations using measurement software. CNC video measuring systems are suitable for automated measurements of components with multiple parameters. This method allows a combination of optics, laser and touch probe to be used for measurement.