Gallery

Range of our accredited services

We are accredited according to these standards:

-

ČSN EN 60068-2-6 - sinusoidal vibration tests, which determine the ability of components, equipment and other objects to withstand specified degrees of severity of sinusoidal vibrations

-

ČSN EN 60068-2-27 - detection of mechanically weak points and / or degradation of specified performance parameters, or accumulated damage or degradation caused by impact

-

ČSN EN 60068-2-53 - testing of equipment and components in combined climatic and dynamic conditions of operational stress

-

ČSN EN 60068-2-64 - random broadband vibration testing and is intended for general use for components, equipment and other products that may be exposed to vibrations arising due to environmental influences during transport or operation

Gallery

We offer various mechanical durability tests combined with temperature and humidity:

- Fatigue vibration tests (sinus - sweep and spot, random)

Exposure of the test specimen to sinus or random vibrations in a certain range of frequencies for a defined time interval at a given load (deflection, speed and acceleration). -

Shock tests

The tested specimen is exposed to sudden and hard shocks, which may occur, for example, during transport, handling or unexpected situations. -

Resonance analysis

Determination the resonance frequencies in the tested product based on the comparison of the response values from the specimen and the vibration exciter using accelerometers. - Vibration tests combined with temperature and humidity

In many cases, the tested products are not only affected by vibrations, but also by environmental influences such as temperature or humidity.

Gallery

Our technology

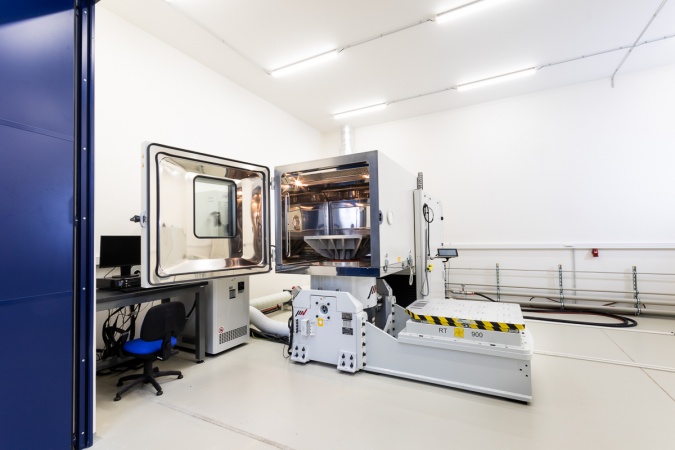

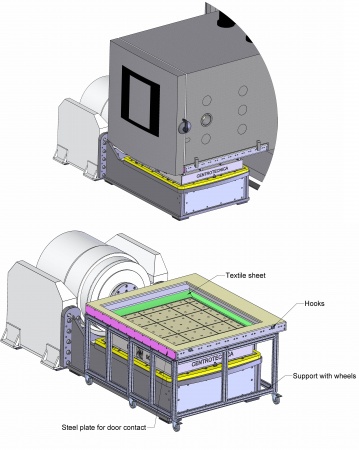

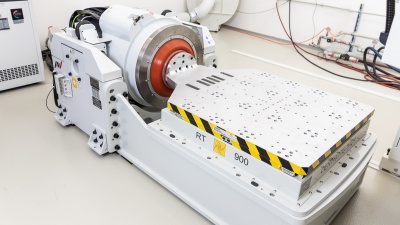

We are able to provide tests in all three axes (X, Y, Z), at defined temperatures and humidity. Our laboratory is equipped with the technologically advanced electrodynamic vibration system IMV, incl. the Centrotecnica slip table and the Weisstechnik climatic chamber for vibration tests. This makes the test preparation procedure more effective and reduces operating costs. We can therefore offer cheaper test solutions which retain a high quality of services. Examples of advantages and timeless solutions of the technology used are:

- Patented ECO-shaker technology’s advantages:

- Cost and energy efficient

- Higher shock velocity up to 4,6 m/s

- Quiet operation

- Predictive maintenance, which means higher operability

- Directive connection of vibration system and climatic chamber

- In both vertical and horizontal direction

- Quick change of vibration direction

- No need of time-consuming installation of thermo barriers

- RT rail slip table with the possibility of replacement of the slip desk with different sizes

- Achieving high temperature and humidity stability during vibration tests

- Temperature range of -70 to +180 °C

- Humidity range of 10 to 95 % r. h.

- Temperature gradient up to 5 K/min

- Vibration controller K2+

Gallery

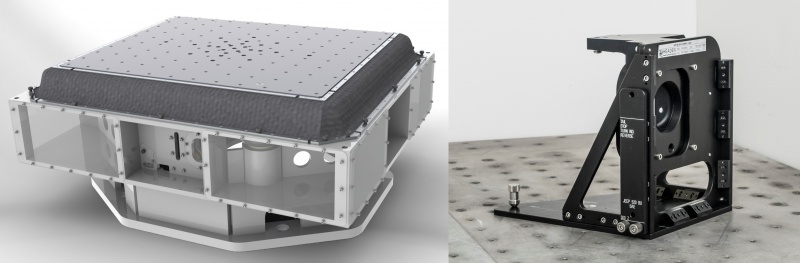

Fixture

Vibration tests are not only about the tests themselves, but also about the appropriate fixture device and method. Therefore, if you do not have your own fixtures for tested specimens, we are able to design them for you in cooperation with our suppliers, from head expanders, thermal barriers, cubes to fixtures for special applications or complicate specimens.

Gallery

Compliance with another standards and requests

- Squeak & Rattle tests

Measurement of noise generated when certain frequencies of the test specimen are reached.

Our laboratory is able to test in accordance with different kinds of standards, such as:

- ČSN EN 60068-2-29

- ČSN EN 60068-2-80

- ČSN EN 61373

- ISO 16750-3

- MIL-STD-810

- VW 80000, Daimler, BMW, Ford, GM, Nissan specifications

- and others

For each of your requirements, even if it is not according to the standards above, we will first of all simulate the test run depending on the technology we use and then we will tell you whether we completely meet your requirements or propose an alternative solution.

Gallery

How do we do it?

It’s easy to try us! Just follow these simple instructions:

- Submit your test requirements to us (for example, using our inquiry form).

- We strive to conduct your tests using the most appropriate methods. This is why our technician will explore all your requirements and contact you within 24 hours with additional questions or recommendations in case you are not completely sure about your inquiry.

- After clarifying your needs in detail, we will prepare a quote including information about the earliest possible testing date.

- After ordering our services, send us your samples, or you can let us arrange to have them taken to our laboratory.

- We will conduct the required tests.

- After your tests have been completed, we will store your samples until you can personally collect them, or we will send them back to you.

- We usually prepare the corresponding test protocol within 48 hours of completed testing.

Gallery

Test protocol

The results of every test we conduct are output as a test protocol that contains the following data:

- information about the tested sample

- test implementation location and time

- test description

- device identification

- photo documentation of samples before and after testing

- real-time graphical records of testing

- test appendixes, for example, records from measuring active samples or regular inspections, etc.

We can prepare the protocol for you in either Czech or English.

Gallery

Why should you test with us?

There are many reasons for testing with us, the most important being:

- Expertise in the field

Our technicians have many years of experience. They can recommend the most suitable testing method for your samples. But if you know exactly what you want and how to test, we will be your partner and not delay you with additional questions. - Flexibility

Even though we have an extensive portfolio of devices, we understand that quality testing keeps increasing its demands on individual products. Because of our close relationships with testing technology manufacturers and device users, we are able to provide even equipment that we do not currently own. - Reliability

We strive to make sure that you can rely on our word as well as our devices, therefore, all our equipment are regularly calibrated by an accredited laboratory and service by an authorized service company. Since we provide these services in house, we can respond to unexpected complications almost immediately. - Personal approach

We treat every single customer individually. At the beginning of each contract there is always an understanding of your needs and requirements. We will do our best to meet all your requests.