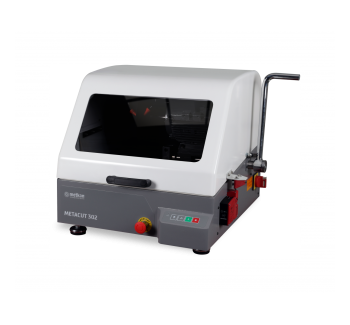

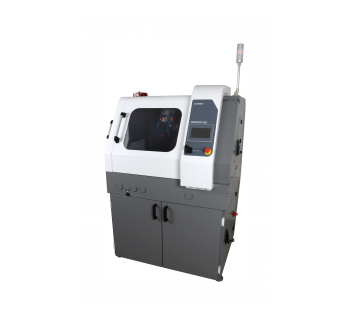

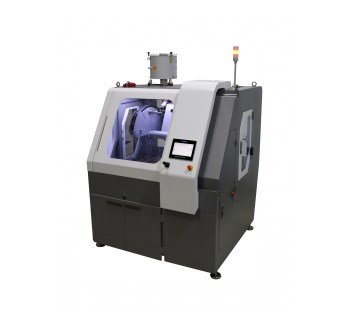

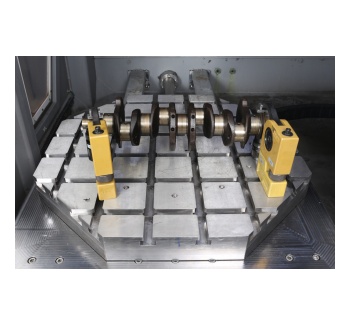

Abrasive cutting

Abrasive Cutting is the most common metallographic cutting method and is generally used for metal specimens and is accomplished with silicon carbide or alumina abrasives in resin or resin rubber bonds. Proper blade selection is required to minimize burning and heat generation during cutting which degrades both the specimen surface as well as the blade cutting efficiency.